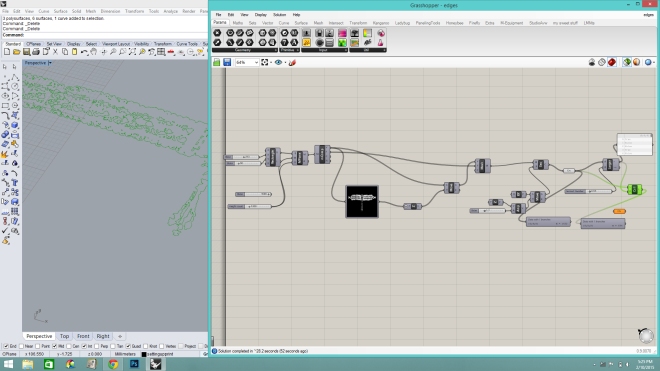

Just a quick panel definition for JnealDesign. They needed a random generator for multiple types of wooden posts as a covering for a building, so I took those sizes and randomly placed them on a surface. So any surface turns into this random covering. All of which are also spaced within the grid of tension lines needed to hold them up.

Tag: Grasshopper

Cool experiment, on to other things.

Works, kind of. I’ve grown tired of finding settings for it. It might need a different nozzle and cooling system to work well.

Grasshopper Definition for Printing Curves.

Using one of Ryan Hoovers definitions as a starting point, I tried to get it to print curves. It needs more work, and a more specific geometry.

“Scanning” with Grasshopper and Drawing With 3d Printer.

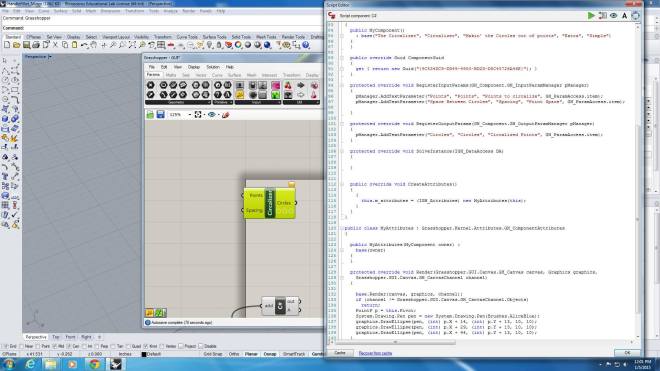

Working on Custom C# components.

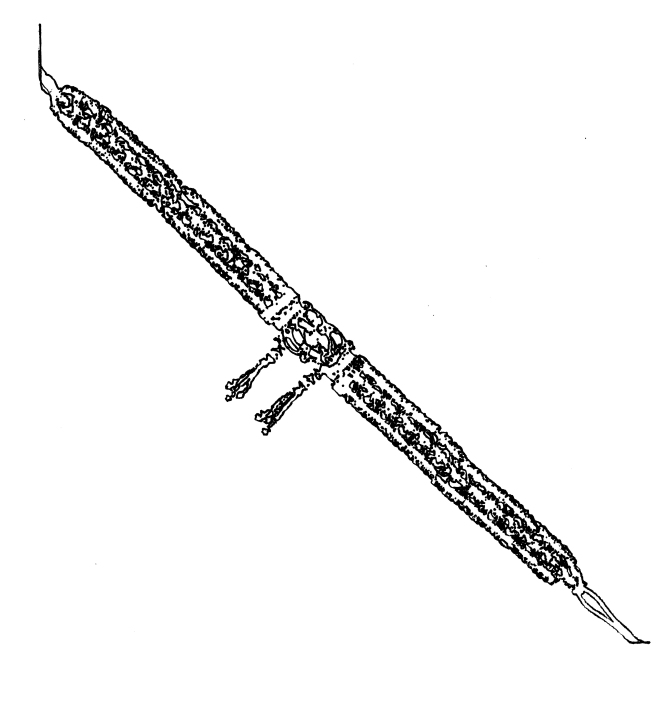

Newer Bow Version

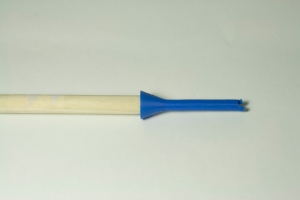

This one is a lot closer, and a lot better than the last iteration. Now that the bow is closer to being done, I can start working on the grasshopper definition again, so anyone can download, customize and make it. I may make a series of other musicians equipment for people to use and download if wanted. I did some experimenting with dying the hair. Here is a sneak peak with a test video follow up soon.

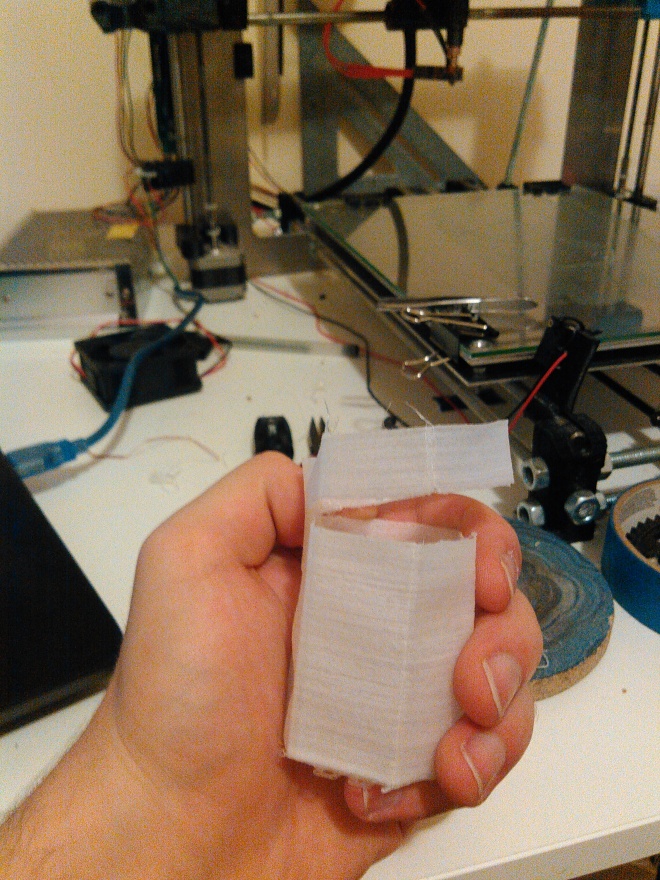

First Working Prototype

Nylon Printing.

After Searching for a bit, I realized that my printer is the only printer around campus that is big enough to print my bow pieces. I was a bit hesitant since I don’t have a heated bed, but I converted my PLA settings to some Nylon settings and it worked amazingly well. I used some PVA glue and printed directly onto the glass. It turned out way better than any of my other prints, which I found a bit ironic. It is extremely leaky however, and there are some settings I need to change for that. It also has to print perimeters extremely slow, from 22mm/s to 44mms, and 44mm/s is pushing it, regardless of the printer. However, once it’s printed, it is almost impossible to break by hand. I was trying to print it a little faster than 30mm/s and got exactly one little skipped hole in a hollow vase. I tugged on it with pliers as hard as I possibly could, and after I few minutes, I got a nice clean tear. I’m pretty sure this material will stand up to the tension of a bow. It’s also really flexible in unsupported directions, and snaps right back. I may be able to print the hair with this as well….

New forms, and better progress

I’ve come up with a more sturdy design, and it seems to work a lot better than the earlier connection methods. I’m still messing around with forms for the stick of the bow, but I decided to try out printing in nylon. There aren’t any printers big enough in the department i’m in, and the printer I use is strictly for pla. So recently i’ve been creating configs for some new printers in the interactive arts department.

I’ll post pictures of the newer version of the frog attachments soon. I’m having trouble thinking of a way to attach the stick to the frog connector, without changing it’s octagonal shape, which many string players have suggested should stay the same, so no one has to relearn how to hold the bow.

Grasshopper Definition for connections to metal rods and wooden dowels

I spent some time making a design that works with connecting to a dowel as the stick of the bow.

However, the wooden dowel diameter needed makes it hard to position the piece that connects the frog and the stick to print. I started messing with settings to see how to make it work, and I got an ‘ok’ one out of it, but if it’s necessary to change slic3r settings for one piece, then it’s not a good piece. It works a lot better for the smaller sized metal rods, but i’m going to spend a little more time on this wooden dowel connection before I move on.

I also did a stress test on the joints holding the hair for the bow. I pulled on the string as hard as I could to see if it would slip. The string broke instead, which is good news,and less to worry about.